Digiforet's

DIGITAL TWIN

Digital Twin

Cutting-edge scans & factory design

Cutting-edge scanning & 3D data digital twinization

REAL META

Cutting-edge scanning and 3D data digital twin creation

X-Twin

Our Project

디지포레의 최첨단 XR 솔루션을 통해

현실과 가상 세계가 융합된

혁신적인 프로젝트들을

직접 경험해 보세요.

기술의 경계를 넘나들며 새로운 가능성을 열어가는 디지포레의 미래지향적인

비전을 만나보실 수 있습니다

Immersion

Provides users with real-time responses and immersive visual, auditory, and tactile experiences, seamlessly connecting the real and virtual worlds.

Interactivity

Offers intuitive interfaces and responsive systems for users to interact with the virtual world.

Real-time Response

Supports remote collaboration and virtual meetings using graphics, sound, and physical interactions.

Flexibility & Scalability

Must be compatible with various VR and AR devices and allow customizable expansion for enterprise environments.

Dongguk Univ. Jeonggakwon Restoration Project

X-Twin Creation Overview

XR Studio

XR Maker Studio

Dr.Meta

02. Data Optimization

To make 3D data usable and efficient, this step involves cleaning and refining the captured point clouds and complex shapes. Unnecessary information is removed, resolution is adjusted, and intricate forms are simplified to improve model performance and support precise restoration work.

03. Modularization

For restoration, cultural assets are divided into independent modules, with detailed models created for each part. This approach allows restoration work to be carried out on individual modules, reducing potential errors and enhancing overall efficiency and accuracy in the process.

04. Visualizing

3D models are carefully and accurately used to simulate the restoration process and visualize the final results, allowing detailed monitoring of progress and supporting informed decisions to ensure the long-term preservation and integrity of cultural assets.

Head Office|

Room 203, Chungnam VRAR Production Base Center, 45-7, Huimang-ro

46beon-gil, Baebang-eup, Asan-si, Chungcheongnam-do, Rep. of KOREA

Experience Center|

Room 1001 & 1002, KLK UWON CITY, 632, Gukhoe

-daero, Yeongdeungpo-gu, Seoul, Rep. of KOREA

XRVP LAB|

B1, Chungmu-ro Video Center Metaverse Studio, 2,

Toegye-ro 36-gil, Jung-gu, Seoul, Rep. of KOREA

Seoul Research Institute|

Room 706, Yangpyeong-dong Innoplex, 57-5,

Yangsan-ro, Yeongdeungpo-gu, Seoul, Rep. of KOREA

Main Contact

02-2039-7980

Business Department

02-2039-7981

Contact Mail

Copyright(C) DIgiforet All rights reserved.

플랫폼의 한계를 넘어 새로운 가능성으로

Digiforet이 함께합니다.

Real-time Data Integration

실제 물리적 객체나 시스템에서 발생하는 데이터를 실시간으로 수집하여 가상 모델에 반영합니다.

Predictive Analytics and Insights

수집된 데이터를 기반으로 예측 분석을 수행합니다. 잠재적인 문제를 사전에 감지하여 예방적 유지보수나 개선 작업을 가능하게 합니다.

Simulation and Optimization

가상 환경에서 시스템이나 프로세스를 시뮬레이션하여 최적화할 수 있는 기능을 제공합니다.

Interaction and Feedback

실제 시스템과 상호작용하며, 실시간 피드백을 통해 시스템의 동작을 개선하고자 합니다.

01. 3D Data Collection

Based on site surveys and existing documents and photos, advanced 3D scanning technology precisely captures the shape, surface, and intricate details of cultural assets, generating high-resolution point cloud data that is then converted into accurate 3D models.

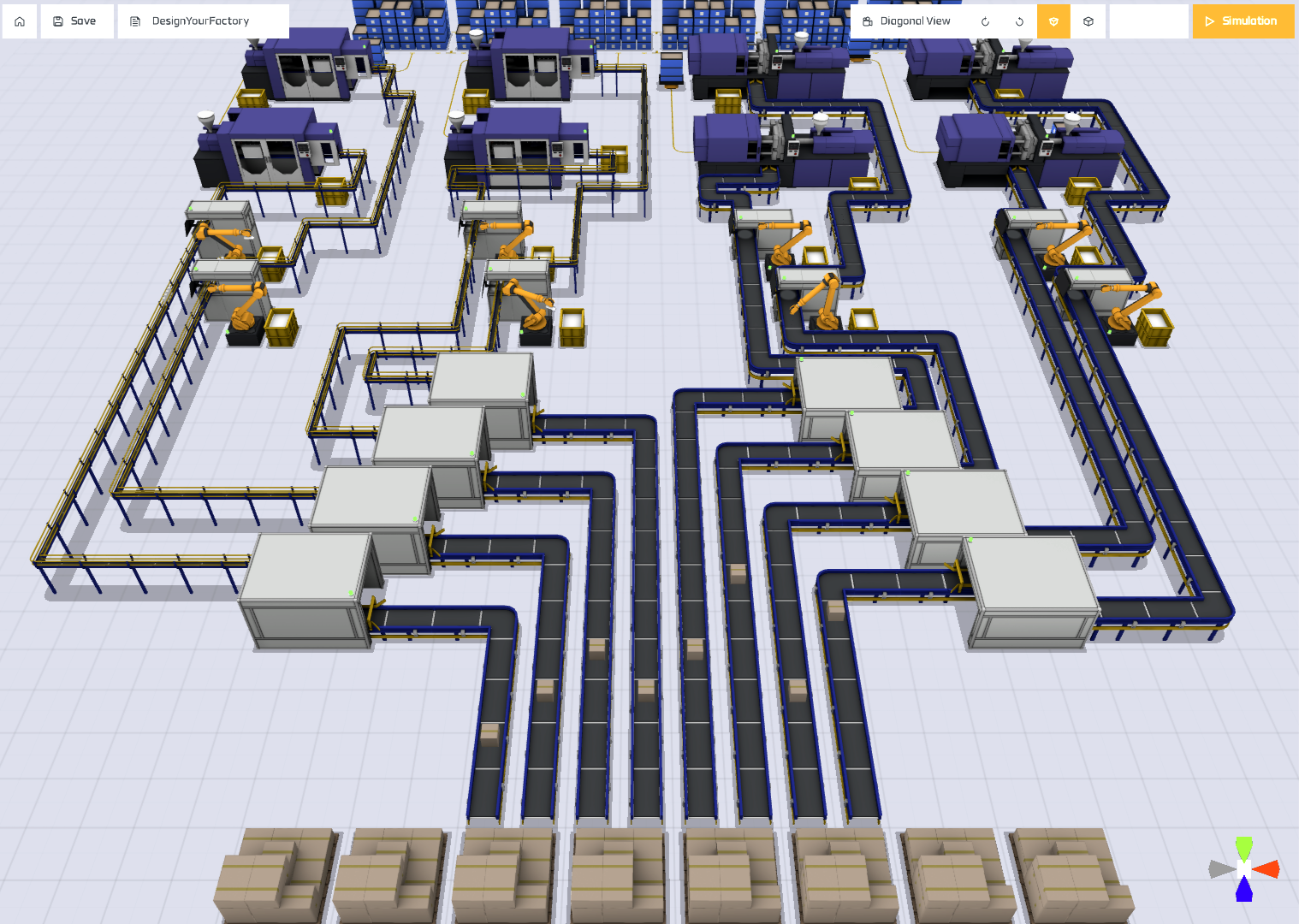

Design

A service that lets you easily design and efficiently manage production lines from manufacturing to delivery in just a few clicks.

Simulation

Applies AI models to designed factories for more accurate productivity and cost analysis and prediction.

Experience

Allows direct factory experience and sharing via web browsers on PC, mobile, and HMD devices.